Revolutionizing Titanium Alloy Surface Treatment: Advanced Anodizing & Color Customization

Introduction

Titanium alloys are widely recognized for their high strength-to-weight ratio, corrosion resistance, and biocompatibility, making them essential in industries such as aerospace, medical devices, electronics, and high-end manufacturing. However, raw titanium surfaces often appear dull or monochromatic.

Through anodizing technology, titanium surfaces can be electrochemically treated to achieve vibrant colors without the use of dyes or coatings. This enhances both the aesthetic appeal and durability of titanium products.

In this article, we will explore the principles, process, required equipment, and color variations of titanium alloy anodizing.

The Science Behind Titanium Alloy Anodizing

Titanium anodizing is an electrochemical process that creates a transparent oxide layer on the metal surface. The thickness of this oxide layer determines the interference colors observed, similar to the way soap bubbles or butterfly wings display iridescent hues.

Key Factors Affecting the Final Color

- Voltage Levels – Different voltages produce different oxide thicknesses, leading to various colors.

- Electrolyte Composition – Common electrolytes include phosphoric acid, sulfuric acid, or oxalic acid solutions, which influence the quality and uniformity of the oxide layer.

- Processing Time – Although voltage primarily determines the color, exposure time can affect consistency.

- Titanium Alloy Type – Different titanium grades (e.g., TC4, TA2) may exhibit slight variations in color.

Titanium Anodizing Process: Step by Step

1. Pre-Treatment

Before anodizing, the titanium surface must be properly cleaned to remove contaminants:

- Degreasing & Cleaning – Using an ultrasonic cleaner or chemical solvent to eliminate oil and dirt.

- Acid Etching – A mild nitric or hydrofluoric acid bath removes the natural oxide layer and enhances surface uniformity.

2. Anodizing Process

The titanium workpiece is submerged in an electrolyte solution and connected as the anode in an electrical circuit.

- Equipment Model: WABPTEK WPS1203H(120V3A)

- Electrolyte Solution: Phosphoric acid or sulfuric acid

- Voltage Range: 10V–120V

- Processing Time: 10 seconds – 2 minutes

- Temperature Control: 20–30°C

3. Color Variations by Voltage

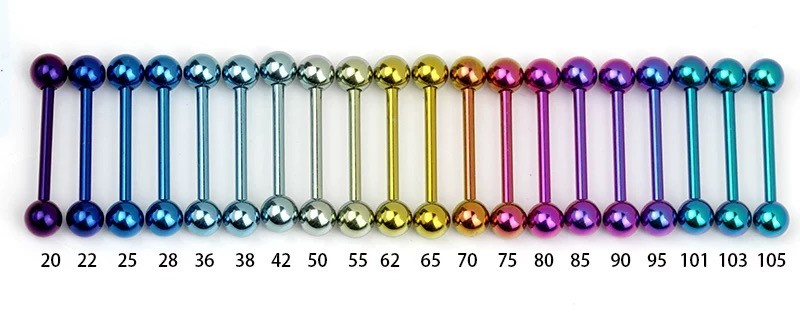

Below are examples of color changes achieved at different voltage levels:

- 10V – Light Gold

- 20V – Purple

- 30V – Blue

- 40V – Cyan

- 50V – Green

- 60V – Yellow

- 70V – Orange

- 80V – Red

- 90V – Dark Purple

- 100V – Deep Blue

The voltage-to-color relationship above is based on the common titanium alloy anodizing color variation pattern. However, different electrolyte compositions, titanium alloy grades, and process parameters may result in variations in the final color.

The image below shows the actual colors obtained through anodizing.

4. Post-Treatment

- Rinsing – The anodized titanium is washed with deionized water to remove electrolyte residues.

- Drying – Air drying or heat drying prevents water stains from affecting the final color.

- Sealing (Optional) – A protective nano-coating or sealing treatment can be applied to enhance durability.

Applications of Titanium Alloy Anodizing

1. Aerospace Industry

Anodized titanium is widely used in aircraft components and satellite structures, offering improved corrosion resistance and aesthetic differentiation.

2. Medical Devices

Due to its biocompatibility, anodized titanium is ideal for surgical instruments, dental implants, and orthopedic implants, where color coding helps distinguish different sizes and types.

3. Consumer Electronics

High-end smartphones, smartwatches, and wireless earbuds utilize anodized titanium casings for enhanced durability and premium aesthetics.

4. Luxury Accessories

Anodized titanium is popular in watches, rings, eyeglass frames, and other high-end accessories due to its scratch resistance and vibrant color options.

Please note that anodized titanium colors may appear different under varying lighting conditions due to light interference and reflection effects.

Conclusion

Titanium alloy anodizing is an eco-friendly, durable, and visually striking surface treatment method that enhances both functionality and aesthetics. By precisely controlling voltage, processing time, and electrolyte composition, manufacturers can achieve a wide range of color effects without using dyes or coatings.

If you are interested in titanium anodizing equipment or customized anodizing services, TIHTM offers state-of-the-art solutions to help you achieve high-quality titanium surface treatments.

Add comment